A Comprehensive Guide on Moving From 3PL to In-House Delivery

Learn how to cut costs by moving from 3PL to in-house delivery amid rising 3PL expenses. A guide to taking charge of your logistics.

As businesses across industries grapple with the escalating expenses imposed by Third-Party Logistics (3PL) providers, these financial pressures have prompted many to contemplate the transition to in-house delivery.

This blog post aims to help you transition to in-house delivery and guide you through the process with our best advice. We’ll take a look at the benefits you’ll experience from cost savings to a renewed sense of control over your supply chain operations. However, we won't shy away from acknowledging the challenges that can appear, but we will offer insights and strategies to conquer these obstacles!

Understanding the 3PL Landscape

Signs It's Time to Consider In-House Delivery

Challenges of Transitioning to In-House Delivery

7 Steps for Moving from 3PL to In-House Delivery

Understanding the 3PL Landscape

3PL is the practice of outsourcing logistics and supply chain management functions. Many companies turn to 3PL providers to leverage their expertise, infrastructure and economies of scale. This outsourcing of specialized knowledge frees companies from the need to develop these competencies in-house, allowing them to focus on their core business activities. 3PL providers offer a sprawling infrastructure network. This includes strategically positioned warehouses, state-of-the-art distribution centers and a well-connected transportation fleet.

While 3PL services indeed offer benefits like streamlined operations and broader reach, the cost challenges associated with them have surfaced prominently in recent times. The cost challenges associated with 3PL services are demanding the attention of businesses across sectors. These surging costs have served as a wake-up call for companies of all sizes and industries. It has prompted a critical reevaluation of their logistics strategies, igniting discussions about the potential benefits of transitioning from 3PL dependency to in-house delivery solutions.

Signs It's Time to Consider In-House Delivery

1. Escalating 3PL Costs: One of the most common and immediate signs that prompt this consideration is the steady rise of 3PL costs. The financial burden imposed by 3PL providers can become unsustainable, eroding profit margins and hindering financial sustainability.

2. Diminishing Sense of Control: Another crucial indicator lies in the erosion of a company's sense of control over its logistics operations. While 3PL providers offer expertise and convenience, they can also distance businesses from their supply chain processes. This detachment can lead to a lack of visibility into operations, making it challenging to ensure compliance with quality standards, meet evolving customer expectations, and swiftly adapt to market fluctuations.

3. Concerns About Service Quality: Beyond cost considerations, concerns about service quality can also serve as a catalyst for change. If businesses witness a decline in the quality of services provided by their 3PL partners, such as delivery delays, damaged goods, or subpar customer experiences, it becomes imperative to reevaluate the arrangement.

SmartRoutes Route Planning Software

Streamline your entire delivery process, all from one platform

Challenges of Transitioning to In-House Delivery

Let's delve into the key challenges that may arise during this transition and explore strategies for navigating them effectively.

Workforce Management

One of the initial hurdles businesses encounter is assembling and managing an in-house logistics team. It entails recruiting, training, and retaining personnel with the right skill sets, from supply chain managers to warehouse staff and delivery drivers.

Technological Integration

Integrating the necessary technology is another critical aspect of the transition. From inventory management systems and order processing software to route optimization tools and delivery tracking platforms, the technology stack needs to be carefully selected, implemented, and seamlessly integrated into existing processes.

Operational Restructuring

Transitioning to in-house logistics often involves a significant overhaul of existing operational processes. This restructuring encompasses everything from warehouse layout and inventory management protocols to distribution network design and order fulfillment workflows. The goal is to optimize efficiency, reduce costs, and enhance overall operational effectiveness.

Minimizing Disruptions

To ensure a seamless transition, businesses must minimize disruptions to ongoing operations. This includes maintaining service levels, meeting customer expectations, and avoiding inventory stockouts or delays during the shift. Effective communication with customers, suppliers, and other stakeholders is crucial to mitigate potential disruptions.

In the following sections, we will offer insights and strategies to help you overcome these hurdles and successfully embark on your journey from 3PL to in-house delivery.

7 Steps for Moving from 3PL to In-House Delivery

1. Hiring and managing staff

Although this step might be obvious, it’s probably one of the most important and definitely needed to be a part of this list. Your entire logistics operation will be based of the creation of a proficient in-house logistics team. Assembling a team with the right blend of skills and expertise is not merely a part of the process; it is the process. Here's a detailed exploration of this pivotal step:

- Identifying the Right Skill Sets: The first step is identifying the specific skills and expertise you need. This includes roles such as supply chain managers, inventory analysts, warehouse supervisors, fleet managers and delivery drivers. Each role demands a unique set of competencies and qualifications. It's crucial to understand your organization's requirements thoroughly before initiating the hiring process.

- Recruitment Strategies: With a clear understanding of the skills you require, the next step is recruitment. You can opt for various recruitment strategies, from advertising job openings on job boards to partnering with staffing agencies. However, consider not only the technical skills but also the cultural fit and alignment with your organization's values when selecting candidates.

- Onboarding and Training: Once you've selected your team members, it's essential to invest in onboarding and training programs. This is particularly important if your new hires are transitioning from other roles or industries. These programs should not only cover the technical aspects of their roles but also familiarize them with your company's culture, values and operational processes.

- Clear Roles and Responsibilities: Clearly defined roles and responsibilities are pivotal to ensure a smooth transition. Every team member should understand their role within the broader logistics operation.

Hiring and managing staff for your in-house logistics team is not just about filling positions; it's about assembling a dynamic, adaptable, and skilled group of individuals who will drive your logistics strategy forward. This phase is not only foundational but also represents a significant opportunity to set the tone for a successful transition from 3PL to in-house delivery.

2. Finding a distribution centre

The journey from Third-Party Logistics (3PL) to in-house delivery hinges significantly on securing an optimal distribution center, the central hub where warehousing and distribution activities occur. This will contribute not only to cost-effective operations but also to streamlined processes and enhanced customer satisfaction.

The cornerstone of a successful distribution center is its strategic location. When choosing where to set up, consider factors such as proximity to major suppliers and customers, accessibility to transportation routes (road, rail, air, and sea), and regulatory considerations. Opt for a facility that offers scalability to accommodate your evolving needs. As your business expands, your distribution center should have the capacity to grow with it without the need for a disruptive relocation.

Once you've identified the ideal location, the design and layout of your distribution center play a crucial role. Efficient space utilization is key. Optimization minimizes wasted space, enhances inventory management, and contributes to cost-effective operations.

Your distribution center should be equipped with cutting-edge technology to streamline processes and enhance efficiency. This includes inventory management systems, warehouse management software, logistics software and automation solutions.

You also need to consider if you are offering reverse logistics (collection of old, damaged or unwanted items). This will affect the size of your warehouse and how it’s laid out to be able to differentiate incoming and outgoing orders.

3. Obtain vehicles for your delivery fleet

The first step in obtaining vehicles for your delivery fleet is to assess your operational scale. Consider factors such as the volume of deliveries, the geographical scope of your service and the types of goods being transported. The size and composition of your fleet should align closely with your operational demands.

Once you've assessed your operational scale, the next step is vehicle selection. The choice of vehicles should be driven by your specific needs. For instance, smaller, fuel-efficient vehicles may be suitable for urban deliveries with frequent stops, while larger trucks may be necessary for long-haul transportation. Consider the payload capacity, fuel efficiency, and maintenance requirements of each vehicle type in relation to your delivery profile.

Opt for vehicles with fuel-efficient engines or explore alternative fuels and propulsion technologies such as electric or hybrid vehicles. Not only do these choices reduce operational costs, but they also align with sustainability goals, potentially offering long-term cost savings.

It’s a good idea to choose vehicles known for their reliability and durability. Regular maintenance schedules should be established and adhered to diligently to minimize downtime and unexpected repair costs. A well-maintained fleet contributes to smoother operations and enhances customer satisfaction.

Throughout the process of obtaining vehicles for your delivery fleet, keep a keen eye on logistics cost management. Evaluate the total cost of ownership, including vehicle purchase or lease costs, fuel expenses, maintenance, insurance, and personnel costs. Efficient cost management is essential for maintaining profitability and competitiveness.

4. Equipment purchase or hire

The first step in equipment acquisition is a comprehensive assessment of your equipment needs. This entails evaluating the specific requirements of your logistics operation, from material handling and inventory management to loading and unloading processes. Consider factors such as the types of goods you handle, their packaging and the frequency of handling.

Once you've identified your equipment needs, the next step is equipment selection. Opt for equipment that aligns precisely with your operational demands. This can include pallet jacks, forklifts, conveyors and other material handling machinery. Many equipment options are equipped with technology solutions such as automation, sensors and data analytics. Don't forget to consider equipment as basic as the best phones for delivery drivers, they might not be the first thing you think of but the small things make a big difference! These technologies not only improve operational efficiency but also provide valuable insights for process optimization. Implement safety measures such as safety training, protective gear, and equipment safeguards to prevent accidents and injuries.

5. Distribution and order fulfillment systems

At the core of efficient distribution and order fulfillment lies inventory management. Implement a comprehensive system that provides real-time visibility into your inventory levels, locations and product specifics. This system empowers you to optimize stock levels, reduce carrying costs and prevent stockouts or overstock situations.

Quick and accurate order processing is essential in meeting customer expectations and reducing operational costs. Utilize order processing systems that automate order entry, verification and fulfillment. These systems should seamlessly integrate with your inventory management platform to ensure real-time availability checks and order accuracy.

Implement tracking systems that provide real-time visibility into the status of orders and shipments. Customers, both B2B and B2C, expect to know where their orders are at any given moment.

Integrate demand forecasting capabilities into your distribution and order fulfillment systems. These systems use historical data and predictive analytics to anticipate demand trends accurately. With precise demand forecasts, you can optimize inventory levels, reduce carrying costs, and respond swiftly to changing market conditions.

6. Performance metrics

The first step in establishing delivery performance metrics is to define your KPIs. These should align closely with your logistics goals and objectives. KPIs can span various aspects of your in-house delivery operations, including delivery timeliness, order accuracy, cost per delivery, inventory turnover and customer satisfaction.

To navigate effectively, you need to monitor your KPIs in real-time. Modern technology and data analytics provide tools to track and measure these metrics continuously. Real-time monitoring allows you to identify issues promptly and make immediate adjustments. For instance, if delivery times start slipping, real-time data can help you identify the root cause and take action before it becomes a problem.

Performance metrics are not static; they evolve as your logistics operation matures. Embrace a culture of continuous improvement by regularly reviewing and refining your KPIs. As your business grows and market conditions change, you may need to adjust your metrics to reflect new goals and challenges.

7. Employ delivery software

One of the primary functions of delivery software is route planning optimization. These software solutions leverage advanced algorithms and real-time data to determine the most efficient delivery routes. They take into account factors such as traffic conditions, delivery windows and vehicle capacity. By optimizing routes, you reduce fuel consumption, minimize transit times, and ensure that your drivers reach their destinations with precision.

Delivery software automates the scheduling process, taking into account driver availability, workload, and legal restrictions on driving hours. It ensures that your drivers' schedules are optimized for maximum efficiency while complying with regulatory standards.

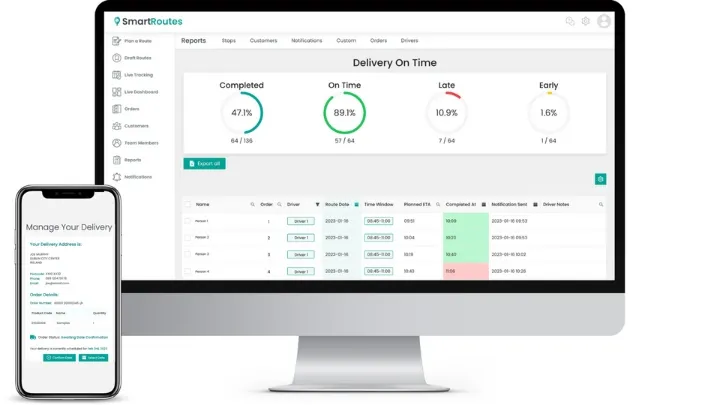

Modern delivery software offers real-time tracking and visibility into your delivery operations. This feature provides real-time updates on the location of your delivery vehicles and the status of individual deliveries. Delivery software enables you to keep your customers informed every step of the way. Automated notifications, such as order confirmation, delivery ETA, and delivery completion, enhance the overall customer experience.

Look for delivery software solutions that offer proof of delivery capabilities. This includes digital signature capture, photo verification, and barcode scanning. These features not only provide evidence of successful deliveries but also reduce disputes and liability issues.

(SmartRoutes is SUPER simple to set up, check our our guide on how to set up SmartRoutes in less than five minutes.)

SmartRoutes Delivery Software

Streamline your entire delivery process, all from one platform

Looking to Move your Delivery Operations In-House?

Escalating 3PL costs, dwindling control and concerns about service quality are all indicators that may prompt you to consider bringing your delivery operations in-house. The benefits of in-house delivery are multifaceted. They include cost savings, heightened control and enhanced flexibility. By bringing logistics in-house, you gain the power to streamline operations, optimize routes, and respond swiftly to market changes.

Transitioning from a well-established 3PL partnership to in-house delivery is not without its challenges. Workforce management, technological integration, operational restructuring, and a steep learning curve are hurdles to overcome. However, these challenges are not impossible to overcome. With the right planning and ongoing commitment to improvement, you can navigate this journey with confidence.

If you are considering bringing your delivery in-house, why not try out SmartRoutes advanced delivery management software? We offer a free 7 day trial which provides you with firsthand experience of how technology can streamline your in-house delivery operations.

Frequently asked questions

1. What are the cost benefits of transitioning to in-house delivery from 3PL services?

Transitioning to in-house delivery can lead to substantial cost savings by eliminating third-party service fees and allowing for greater control over operational expenses.

2. How can I ensure a smooth transition from 3PL to in-house delivery?

A successful transition requires careful planning, which includes assessing your logistics needs, establishing the right infrastructure, and having a well-defined strategy in place.

3. What technology solutions can help optimize in-house delivery operations?

Technology solutions such as delivery management software, route optimization tools, and real-time tracking systems can significantly enhance the efficiency and effectiveness of in-house delivery.

4. What challenges should I be prepared for when bringing logistics in-house?

Common challenges include workforce management, technology integration, and adapting to the learning curve of managing logistics internally. However, these challenges can be overcome with proper planning and strategies.

5. What are some common strategies for optimizing in-house delivery operations during the transition from 3PL services?

Optimizing in-house delivery operations involves several key strategies, such as route planning, driver scheduling, and real-time tracking. These methods can enhance efficiency and cost-effectiveness during the transition.

If you enjoyed this blog, you might also be interested in: