What is Reverse Logistics?

Explore the intricacies of reverse logistics in our comprehensive guide. Learn how businesses manage returns and enhance customer satisfaction.

E-commerce has undeniably reshaped the way we shop, it’s given us the convenience of exploring and acquiring a world of products without leaving the comfort of our homes. However, e-commerce has its own set of challenges, and one particularly intricate challenge is the substantial volume of returns that accompany online purchases. This is where the concept of reverse logistics comes in. It deals with the tough job of getting items back to where they came from.

Reverse logistics plays a big role in reducing waste, making the most of resources, and keeping customers happy, especially when it comes to online shopping. According to a recent report, the global reverse logistics market was valued at USD 939.43 million in 2022 with projections of a USD 2,986.17 billion market value by 2032, boasting a remarkable compound annual growth rate (CAGR) of 12.3%.

In this blog, we're going to explore the process of reverse logistics, especially when it comes to online shopping. When it’s needed, the benefits, the challenges and so on.

The Difference Between Planned and On-Demand Reverse Logistics

When is Reverse Logistics Needed?

Why Reverse Logistics is Important

The Challenges of Reverse Logistics

How SmartRoutes Can Help you Manage your Reverse Logistics

What is Reverse Logistics?

Reverse logistics refers to the process of managing the return of goods from their final destination back to the manufacturer or distributor. Unlike traditional logistics that focus on getting products from point A to point B, reverse logistics involves the intricate coordination of collecting, transporting and sometimes even disposing of items. This process is not just about handling returns but also encompasses scenarios such as recycling, refurbishing or even proper disposal of products.

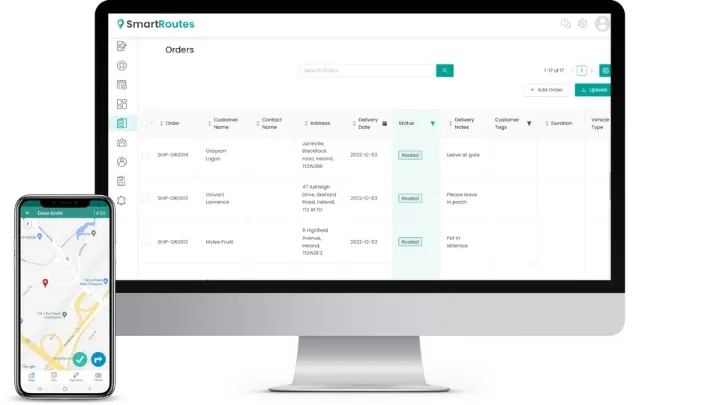

SmartRoutes Route Planning Software

Streamline your entire delivery process, all from one platform

The Difference Between Planned and On-Demand Reverse Logistics

Reverse logistics can be broadly categorized into two types: planned and on-demand. Each has its own unique characteristics, challenges and advantages, ultimately contributing to the seamless orchestration of the reverse supply chain.

Planned Reverse Logistics

Planned reverse logistics involves a proactive and structured system meticulously designed to handle returns, exchanges and other post-consumption scenarios. This approach hinges on the anticipation of the need for reverse movement of products, with processes and strategies established well in advance. Businesses employing planned reverse logistics understand that a smooth return process enhances customer satisfaction, strengthens brand loyalty and optimizes resource allocation.

Companies adopting planned reverse logistics create standardized processes for handling returns, refurbishment, recycling and disposal. By analyzing historical data, businesses can predict return volumes and allocate resources accordingly. This prevents bottlenecks, reduces unnecessary costs, and ensures a timely response to return requests.

On-Demand Reverse Logistics

On the other hand, on-demand reverse logistics comes into play when unexpected scenarios arise. This could include sudden product recalls, unexpected returns due to defects, or urgent collection requests. While planned reverse logistics focuses on consistency and anticipation, on-demand reverse logistics requires agility and rapid response.

Businesses employing on-demand reverse logistics must be prepared to swiftly adjust their operational strategies to accommodate unforeseen events. This includes rerouting delivery vehicles, reassigning resources and reallocating the workforce.

While planned and on-demand reverse logistics differ in their focus and execution, they share core principles crucial for success. Whether planned or on-demand, reverse logistics should be executed with maximum efficiency. This includes optimizing routes, minimizing delays, and ensuring that items are processed or returned in a timely manner. In both scenarios, the customer remains at the center. An impeccable reverse logistics process enhances customer satisfaction, fosters trust and showcases the commitment of a business to post-purchase care. Technology is a common thread weaving through both planned and on-demand reverse logistics. Advanced tracking systems, real-time communication platforms, and data analytics contribute to seamless execution and informed decision-making.

When is Reverse Logistics Needed?

Reverse logistics is a strategic approach that ensures a seamless transition for goods moving in the opposite direction – from their final destination back to their origin or designated collection points. Several scenarios require the implementation of reverse logistics such as:

1. Pick-up and Delivery Services

Businesses offering delivery services find themselves at the forefront of reverse logistics. The process involves not just the one-way journey of delivering products to customers but also orchestrating the collection of items from them. This scenario commonly arises when customers wish to have larger items like furniture or appliances removed for repairs, recycling or proper disposal. Reverse logistics in this context seamlessly integrates collection needs into the overall delivery strategy, optimizing routes and ensuring a hassle-free experience for both the business and the customer.

2. Returns and Exchanges

In the bustling realm of e-commerce, returns and exchanges are par for the course. Reverse logistics comes into play as customers initiate the process of returning or exchanging products for various reasons – from mismatched expectations to defects or damages. An adept reverse logistics system streamlines this process, enabling businesses to assess returned items, determine their disposition (refurbishment, resale, or disposal), and ensure timely refunds or replacements. This not only boosts customer loyalty but also maintains the integrity of the supply chain.

3. Large Appliance or Furniture Removal

The purchase of new items, such as large appliances or furniture, often requires the removal of their older counterparts. Whether for reasons of space, aesthetics, or functionality, this removal process is a delicate task that demands precision. Reverse logistics takes charge in orchestrating the seamless removal of these items, ensuring they are properly collected, handled, and directed toward appropriate channels – whether for refurbishment, recycling or disposal. This not only alleviates the burden on customers but also contributes to sustainable practices.

4. Rental Returns

Companies offering rental services thrive on the temporary exchange of products. However, the end of the rental period beckons the return of these items to the original provider. Reverse logistics plays a pivotal role in managing this transition, offering a reliable and efficient way to retrieve rented items. This process involves setting up seamless mechanisms for customers to return rented goods, ensuring that the items are collected, evaluated, and reintegrated into the inventory if appropriate.

Benefits of Reverse Logistics

There are many benefits you can expect from offering efficient reverse logistics as a part of your service:

Cost Savings:

By optimizing the return process, businesses can effectively mitigate unnecessary costs that often arise from inefficient handling of returns. Properly managed reverse logistics reduces expenses related to storage, transportation, and disposal of unwanted items. Items that are refurbished, resold, or recycled contribute to revenue streams that counterbalance the costs associated with reverse logistics, ultimately leading to a healthier bottom line.

Customer Satisfaction:

An integral part of customer satisfaction is the ease with which they can initiate returns or exchanges. Streamlined reverse logistics processes that prioritize clear communication, swift action and efficient handling of returns elevate the overall customer experience. When customers encounter a hassle-free return process, their loyalty to the brand strengthens. This loyalty not only translates into repeat business but also cultivates positive word-of-mouth recommendations, enhancing the brand's reputation in the market.

Sustainability:

In an era marked by growing environmental consciousness, businesses that align with sustainable practices stand out as pioneers. Reverse logistics plays a pivotal role in this endeavor. Proper disposal and recycling of products that have reached the end of their lifecycle contribute to the reduction of waste and the conservation of resources. By integrating sustainable practices into their reverse logistics strategies, businesses demonstrate their commitment to environmental responsibility.

Why Reverse Logistics is Important

For many, the importance of forward logistics – the seamless movement of products from manufacturers to consumers – often takes center stage. However, as the complexities of the modern business landscape evolve, reverse logistics emerges as a critical counterpart. In a world where customer expectations, environmental consciousness, and operational efficiency converge, reverse logistics is not just a choice but a strategic imperative.

As e-commerce and the on-demand economy reshape the way consumers shop, the need for efficient returns, exchanges and proper disposal practices becomes paramount. Consumers now expect hassle-free returns, seamless exchanges and responsible recycling options. Businesses that fail to meet these expectations risk losing not only revenue but also the trust of their customer base.

Businesses are increasingly being held accountable for their ecological footprint. Reverse logistics plays an integral role in this sustainability shift. Proper disposal, recycling, and refurbishment of products ensure that materials are repurposed, waste is minimized, and responsible practices are upheld. As governments and consumers alike prioritize eco-friendly practices, integrating sustainable reverse logistics becomes a strategic advantage and a moral obligation.

The Challenges of Reverse Logistics

From the moment a product embarks on its return journey, businesses encounter a series of challenges that demand strategic solutions and proactive approaches:

- Coordinating the Return Process Efficiently: Coordinating this process efficiently requires meticulous planning and coordination across various touchpoints – from customers initiating returns to the collection, evaluation, and potential reintegration of items into the supply chain. The challenge lies in creating a process that ensures items are not lost, damaged, or mismanaged during their return journey, while also accounting for varying return reasons and product conditions.

- Optimizing Routes to Minimize Backtracking: Efficient route optimization is a cornerstone of logistics success, but the complexities of reverse logistics introduce unique challenges. Businesses must navigate the intricate puzzle of minimizing backtracking – ensuring that return routes are synchronized with delivery routes to avoid unnecessary mileage, fuel consumption and operational costs.

- Handling Items for Refurbishment or Disposal: The reverse logistics journey often involves products that are returned for various reasons – defects, damages, end-of-life disposition or refurbishment. Each of these scenarios demands a tailored approach to handling items. Efficiently managing items for refurbishment involves assessing their condition, determining the extent of repairs needed and ensuring a seamless process that brings items back to a state of resale.

- Maintaining Clear Communication with Customers: Customers initiating returns or exchanges expect updates on the status of their requests, estimated processing times and details regarding refunds or replacements. Businesses must establish effective communication channels that keep customers informed at every step of the journey. Failure to provide timely and accurate information can lead to frustration, eroding trust in the brand.

- Adapting to Dynamic Situations: While planned reverse logistics strategies offer structure, the realm of returns is inherently unpredictable. The need to adapt to dynamic situations – such as unexpected spikes in return volumes, last-minute changes in collection requests, or urgent product recalls – poses a significant challenge. Businesses must cultivate agility in their reverse logistics operations, empowering their teams to respond swiftly to changing circumstances without compromising efficiency or customer experience.

How SmartRoutes Can Help you Manage your Reverse Logistics

SmartRoutes offers a comprehensive delivery management platform that empowers businesses to seamlessly integrate reverse logistics into their operations. By bridging the gap between the traditional forward journey and the dynamic reverse journey of products, SmartRoutes becomes an indispensable tool for logistics managers, warehouse professionals and business owners alike.

SmartRoutes understands that the reverse logistics landscape requires precision and adaptability. The platform improves how businesses handle this complex process by allowing logistics managers and warehouse professionals to include collection information alongside deliveries. This simple yet powerful feature enables better planning and optimization of routes, ensuring that the reverse journey of items aligns harmoniously with the overall delivery strategy.

Key Features for Reverse Logistics Management:

SmartRoutes comes equipped with an array of features tailored to meet the unique challenges of reverse logistics:

Customized Parameters: The platform accommodates specific collection needs, such as item size, weight and vehicle capacity. This ensures that route planning is not just efficient but also tailored to the specific requirements of reverse logistics.

Efficiency through Zone Groups: SmartRoutes intelligently groups deliveries and collections within the same vicinity. This innovative approach helps businesses avoid backtracking, reducing mileage, fuel consumption, and operational costs.

Real-time Tracking: Operational visibility is crucial in reverse logistics. SmartRoutes provides businesses with the ability to monitor the progress of both deliveries and collections in real-time. This transparency enhances decision-making and customer satisfaction.

Dynamic Changes: The fluid nature of reverse logistics demands adaptability. Smartroutes enables on-the-fly adjustments to routes, ensuring that businesses can respond swiftly to changing circumstances and maintain operational efficiency.

Customer Notifications: Keeping customers informed is pivotal for a positive experience. Smartroutes offers estimated time of arrivals and live updates, ensuring that customers are well-informed about the status of their collections. This proactive communication enhances their overall interaction with the brand.

Use SmartRoutes for Your Reverse Logistics Process

To experience the power of SmartRoutes in managing your reverse logistics, we invite you to try it with our 7-day free trial. See how SmartRoutes can optimize your reverse logistics processes, enhance customer satisfaction and elevate your overall supply chain management.

Frequently asked questions

1. How Does Reverse Logistics Differ from Forward Logistics?

Reverse logistics manages product returns and the flow of goods from consumers back to manufacturers or disposal points, whereas forward logistics focuses on moving products from manufacturers to consumers.

2. What Are the Key Benefits of Implementing a Reverse Logistics Strategy?

Implementing a reverse logistics strategy offers benefits such as cost savings, improved customer satisfaction, environmental sustainability, regulatory compliance, and reduced waste.

3. What Are Some Common Challenges in Reverse Logistics?

Common challenges in reverse logistics include dealing with the varying condition of returned products, the costs of reverse transportation, complex inventory management, meeting customer return expectations, and managing responsible disposal and recycling.

If you enjoyed this blog, you might also be interested in: